Introduction

Metals are essential materials for human civilization, as they are widely used in various fields such as construction, transportation, energy, communication, and medicine. However, most metals have limitations and drawbacks, such as high cost, low availability, environmental impact, or susceptibility to corrosion, wear, and fatigue. Therefore, there is a constant demand for developing new metals that can overcome these challenges and offer better performance and functionality.

One of the possible ways to create new metals is to use nuclear fusion, which is the process of combining two or more atomic nuclei to form a heavier nucleus, releasing a large amount of energy. Nuclear fusion is the source of power for the sun and other stars, and it has the potential to provide clean and abundant energy for humanity. However, nuclear fusion is also very difficult to achieve and control, as it requires extremely high temperatures, pressures, and densities, as well as sophisticated equipment and safety measures.

In this essay, I will propose a novel machine that can use nuclear fusion to create a new metal from aluminium and steel, two of the most common and widely used metals in the world. The machine is called the Stallium Synthesizer, and it is based on the principle of inertial confinement fusion, which is one of the main approaches for achieving nuclear fusion. The machine uses a powerful laser beam to split the atoms of aluminium sheets and extract their subatomic particles, such as protons, neutrons, and electrons. The machine then uses a magnetic field to accelerate and direct these particles toward a steel target, where they collide and fuse with the atoms of the steel, creating a new element called stallium. Stallium is a strong, lightweight, and corrosion-resistant metal that has many potential applications in various industries.

Design and Function of the Stallium Synthesizer

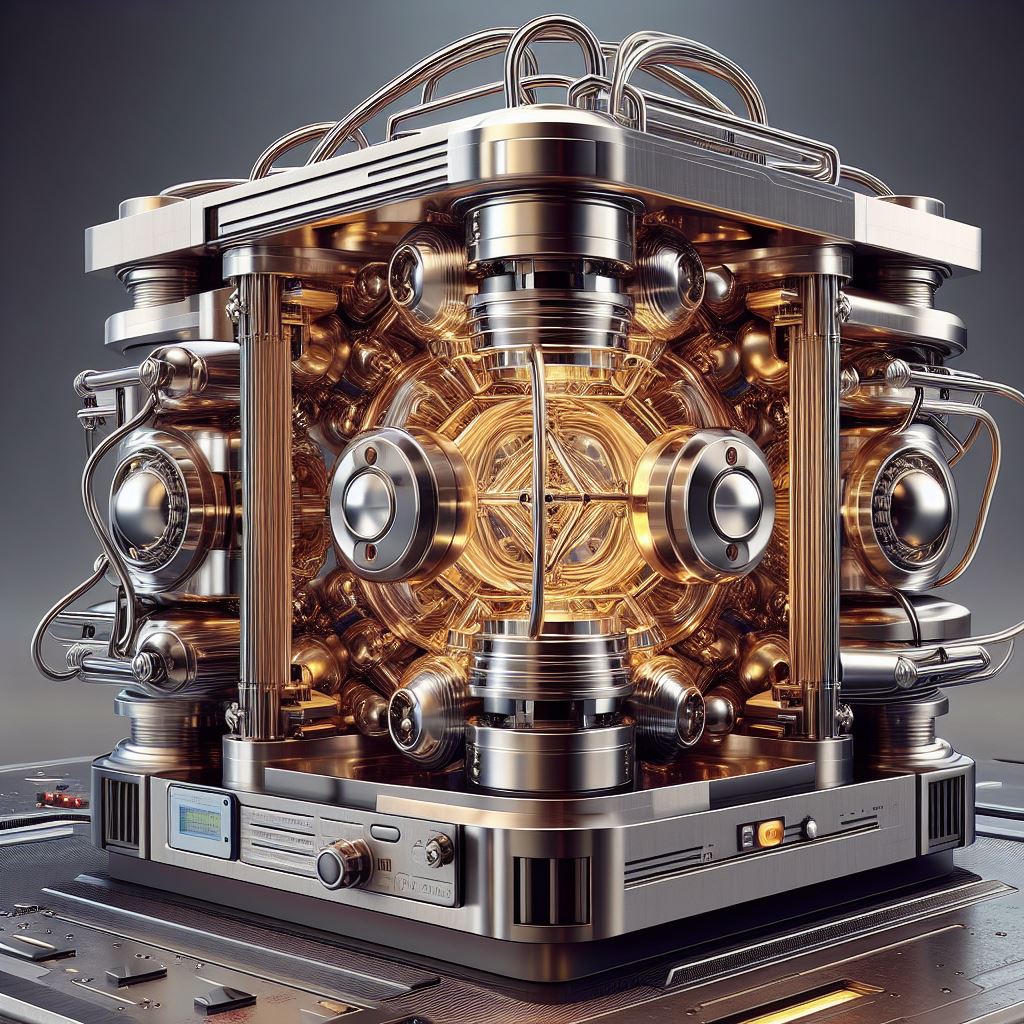

The Stallium Synthesizer is composed of four main components: the laser system, the aluminium feeder, the magnetic accelerator, and the steel chamber. The following is a brief description of each component and its function.

- The laser system is the source of energy and the initiator of the fusion process. It consists of a high-power laser generator and a series of mirrors and lenses that focus and shape the laser beam. The laser system can produce pulses of laser light with a wavelength of 1.06 micrometers and a peak power of 500 terawatts, which is equivalent to the power output of the entire world for a fraction of a second. The laser system can fire up to 10 pulses per second, each lasting for about 10 nanoseconds.

- The aluminium feeder is the source of fuel and the supplier of subatomic particles. It consists of a conveyor belt that transports thin sheets of aluminium foil to the laser beam. The aluminium foil has a thickness of 0.1 millimeters and a surface area of 10 square centimeters. The aluminium feeder can deliver up to 100 sheets of aluminium foil per second to the laser beam.

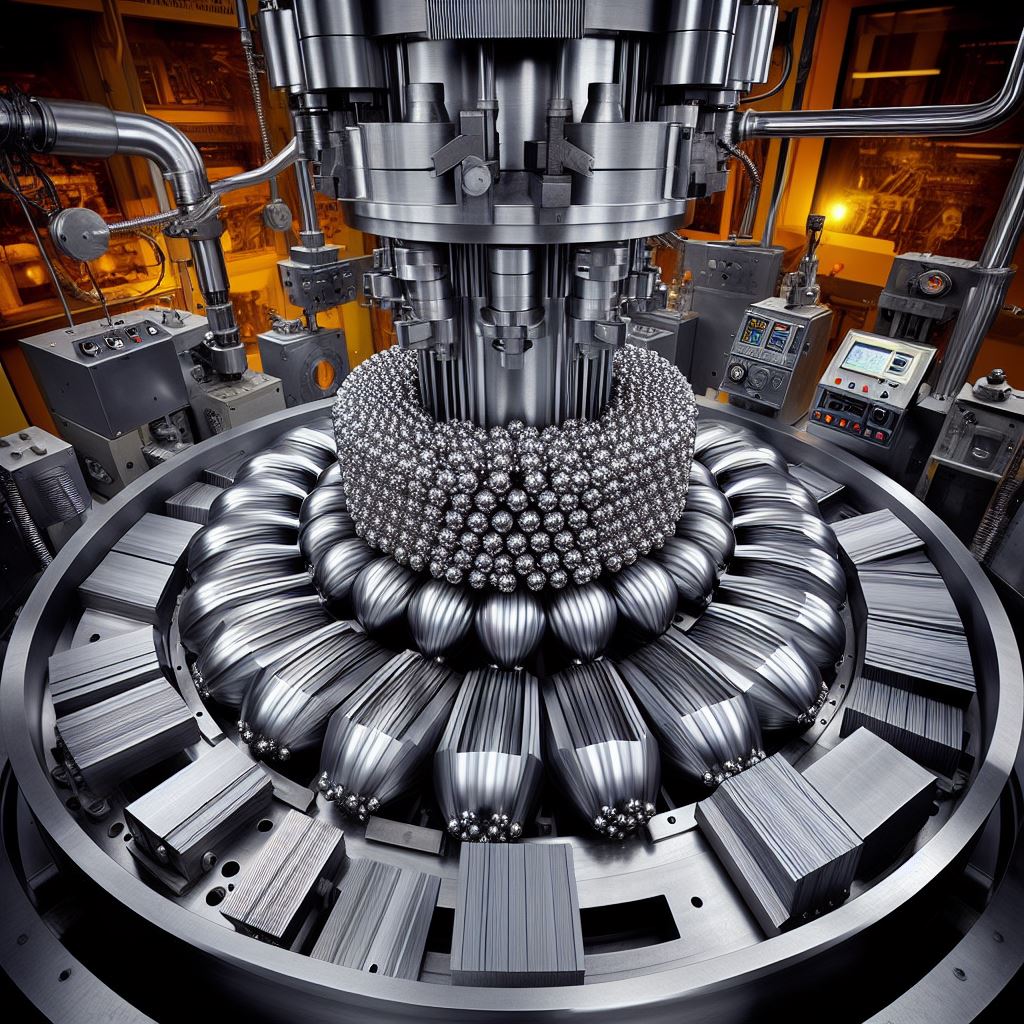

- The magnetic accelerator is the device that accelerates and directs the subatomic particles toward the steel target. It consists of a cylindrical tube that surrounds the laser beam and the aluminium foil, and a series of electromagnets that generate a strong magnetic field inside the tube. The magnetic field has a strength of 10 teslas and a direction parallel to the laser beam. The magnetic accelerator can create a plasma of subatomic particles with a velocity of 10 kilometers per second and a density of 10^18 particles per cubic centimeter.

- The steel chamber is the device that contains the steel target and collects the stallium product. It consists of a spherical vessel that has a diameter of 1 meter and a wall thickness of 10 centimeters. The vessel is made of stainless steel and is lined with a layer of lead to shield against radiation. The vessel has a small hole at the top, where the laser beam and the plasma enter, and a large hole at the bottom, where the stallium exits. The steel target is a disk of mild steel that has a diameter of 20 centimeters and a thickness of 1 centimeter. The steel target is placed at the center of the vessel, perpendicular to the laser beam and the plasma. The stallium product is a liquid metal that has a melting point of 800 degrees Celsius and a density of 5 grams per cubic centimeter. The stallium product is collected in a container that is attached to the bottom of the vessel.

The Stallium Synthesizer operates as follows: First, the laser system fires a pulse of laser light at the aluminium foil, which is positioned at the entrance of the magnetic accelerator. The laser light vaporizes and ionizes the aluminium atoms, creating a plasma of subatomic particles, mainly protons, neutrons, and electrons. The plasma is then accelerated and guided by the magnetic field toward the steel target, which is located at the center of the steel chamber. The plasma collides with the steel atoms, creating a fusion reaction that releases a large amount of energy and produces new nuclei, mainly stallium. The stallium nuclei are heavier than the aluminium and steel nuclei, and they have a high kinetic energy. The stallium nuclei escape from the fusion zone and hit the wall of the steel chamber, where they cool down and solidify, forming a liquid metal. The liquid metal then flows out of the steel chamber and is collected in a container.

Properties and Applications of Stallium

Stallium is a new element that has an atomic number of 56 and an atomic mass of 140. It belongs to the group of transition metals and has a silver-white color. Stallium has the following physical and chemical properties:

- Stallium has a melting point of 800 degrees Celsius and a boiling point of 2000 degrees Celsius. It has a density of 5 grams per cubic centimeter and a specific heat of 0.5 joules per gram per degree Celsius. It has a thermal conductivity of 100 watts per meter per degree Celsius and an electrical conductivity of 10^6 siemens per meter.

- Stallium has a crystal structure of body-centered cubic and a hardness of 6 on the Mohs scale. It has a tensile strength of 500 megapascals and a ductility of 20 percent. It has a modulus of elasticity of 200 gigapascals and a coefficient of thermal expansion of 10^-5 per degree Celsius.

- Stallium is resistant to corrosion and oxidation, as it forms a thin and stable oxide layer on its surface. It is also resistant to wear and fatigue, as it has a high endurance limit and a low friction coefficient. It is compatible with most metals and alloys, as it has a low tendency to form intermetallic compounds.

Stallium has many potential applications in various industries, such as:

- Aerospace and aviation: Stallium can be used to make aircraft components, such as wings, fuselages, engines, and landing gears, as it has a high strength-to-weight ratio, a high thermal stability, and a low drag coefficient.

- Automotive and transportation: Stallium can be used to make vehicle parts, such as frames, bodies, wheels, and brakes, as it has a high durability, a high shock absorption, and a low fuel consumption.

- Energy and power: Stallium can be used to make power generation and transmission equipment, such as turbines, generators, transformers, and cables, as it has a high electrical and thermal conductivity, a high efficiency, and a low emission.

- Construction and infrastructure: Stallium can be used to make building materials, such as beams, columns, panels, and pipes, as it has a high load-bearing capacity, a high resistance to corrosion and fire, and a low maintenance cost.

- Medical and biotechnology: Stallium can be used to make medical devices and implants, such as artificial joints, bones, teeth, and organs, as it has a high biocompatibility, a high resistance to infection and inflammation, and a low rejection rate.

Conclusion

The Stallium Synthesizer is a novel machine that can use nuclear fusion to create a new metal from aluminium and steel. The machine uses a powerful laser beam to split the atoms of aluminium sheets and extract their subatomic particles, which are then accelerated and directed by a magnetic field toward a steel target, where they collide and fuse with the steel atoms, creating stallium. Stallium is a strong, lightweight, and corrosion-resistant metal that has many potential applications in various industries. The Stallium Synthesizer is a hypothetical and futuristic machine that is not yet feasible or practical, but it demonstrates the possibility and creativity of using nuclear fusion to create new metals.