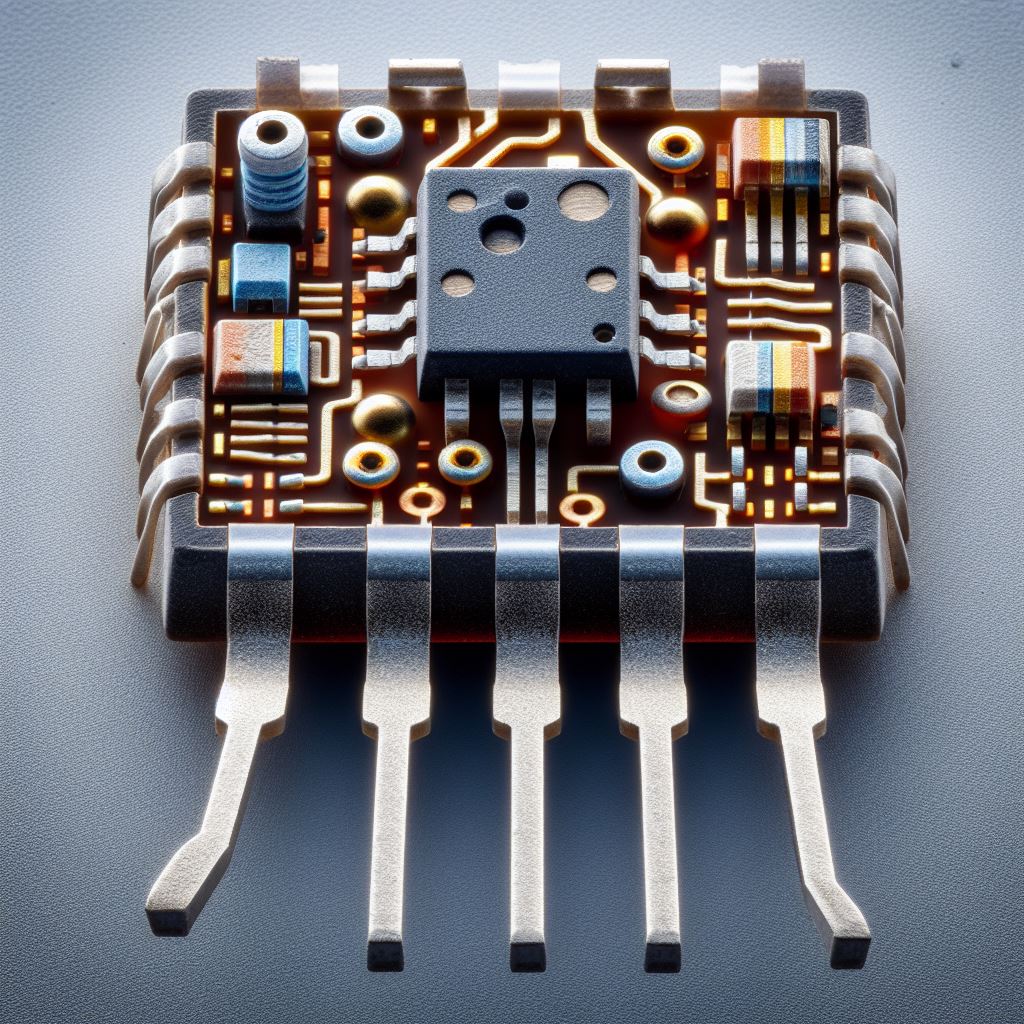

The QuantumFusion IGBT (Insulated Gate Bipolar Transistor) transistor is poised to revolutionize inverter welding technology through the amalgamation of cutting-edge materials and precision engineering. Representing a significant leap forward, this transistor is designed to address critical challenges in the welding industry, offering a confluence of advanced features that redefine performance benchmarks, elevate efficiency, and enhance the adaptability of inverter welders.

1. Advanced Semiconductor Matrix: QuantumFusion’s cornerstone lies in its proprietary semiconductor matrix, a meticulously engineered ensemble of high-performance materials. This matrix optimizes electron mobility within the transistor, thereby substantially reducing on-state voltage drop. The resultant enhancement in quantum efficiency minimizes power losses and maximizes energy conversion rates.

2. Nanosecond Switching Dynamics: Leveraging state-of-the-art semiconductor materials, QuantumFusion achieves unprecedented nanosecond-level switching speeds. This remarkable speed minimizes switching losses, providing the inverter with exceptional responsiveness and control over the welding process. This breakthrough is poised to significantly impact the precision and efficiency of welding operations.

3. Thermally Resilient Composite Construction: QuantumFusion introduces an innovative approach to construction through the integration of advanced composite materials characterized by superior thermal resilience. This feature ensures the IGBT transistor maintains peak performance even in environments with extreme operating temperatures. The result is an extended operational lifespan and heightened reliability under challenging conditions.

4. Adaptable Thermal Modulation: A hallmark of QuantumFusion is its incorporation of an adaptive thermal modulation system. This system dynamically adjusts cooling mechanisms in real-time based on the prevailing operating conditions. By preventing overheating and ensuring optimal temperature control, QuantumFusion facilitates continuous and reliable operation during prolonged welding sessions.

5. Efficient Miniaturization Techniques: QuantumFusion adopts state-of-the-art miniaturization techniques to achieve a compact and lightweight design without compromising performance. This feature is of paramount significance for portable and mobile welding applications, providing welders with unprecedented flexibility and ease of use without sacrificing technological sophistication.

6. Intelligent Control Console: QuantumFusion integrates an intelligent control console, representing the pinnacle of user interface design. This console allows welders to intuitively customize and fine-tune parameters in real-time. Offering comprehensive feedback and analytical insights, the console empowers welders to achieve precise and consistent results across diverse welding applications.

Implications for the Inverter Welder Domain:

- Elevated Energy Efficiency: QuantumFusion’s advanced semiconductor matrix translates into a substantial reduction in energy consumption, promising tangible cost savings and reduced environmental impact.

- Heightened Productivity Levels: The nanosecond switching dynamics and precise control mechanisms significantly enhance welding productivity, enabling expedited and efficient project completion.

- Versatility Across Applications: The compact design, adaptive thermal modulation, and superior construction make QuantumFusion suitable for a myriad of welding applications, ranging from intricate projects to heavy-duty industrial welding.

- Reliability and Endurance: The thermally resilient composite construction and adaptive thermal modulation system ensure QuantumFusion operates with heightened reliability and endurance, mitigating downtime and maintenance expenses.

In conclusion, the QuantumFusion IGBT Transistor represents a paradigm shift in inverter welding technology. Its advanced semiconductor matrix, nanosecond switching dynamics, thermally resilient composite construction, efficient miniaturization, and intelligent control console collectively position it as a benchmark for performance, efficiency, and adaptability within the welding industry. This innovation is poised to propel welding technology into a new era of precision and reliability.