Abstract:

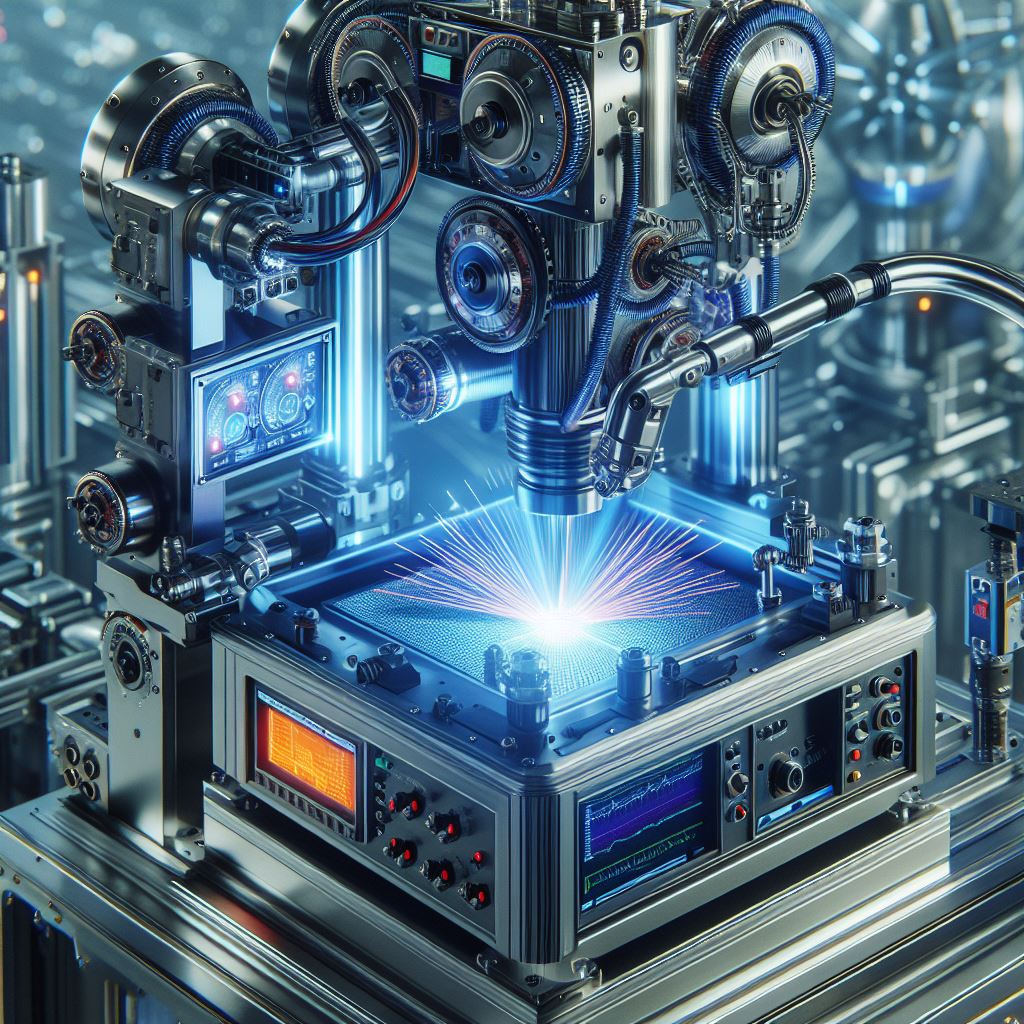

The present invention, herein referred to as the Autonomous TIG Welding System (ATWS), introduces a paradigm shift in Tungsten Inert Gas (TIG) welding technology. The ATWS is equipped with an innovative Vision Feedback System and Adaptive Control Mechanisms, leveraging artificial intelligence to automate welding processes and eliminate the need for extensive operator expertise. This patent details the technical specifications, features, and advantages of the ATWS, positioning it as a pioneering solution in the field of automated welding systems.

Technical Features:

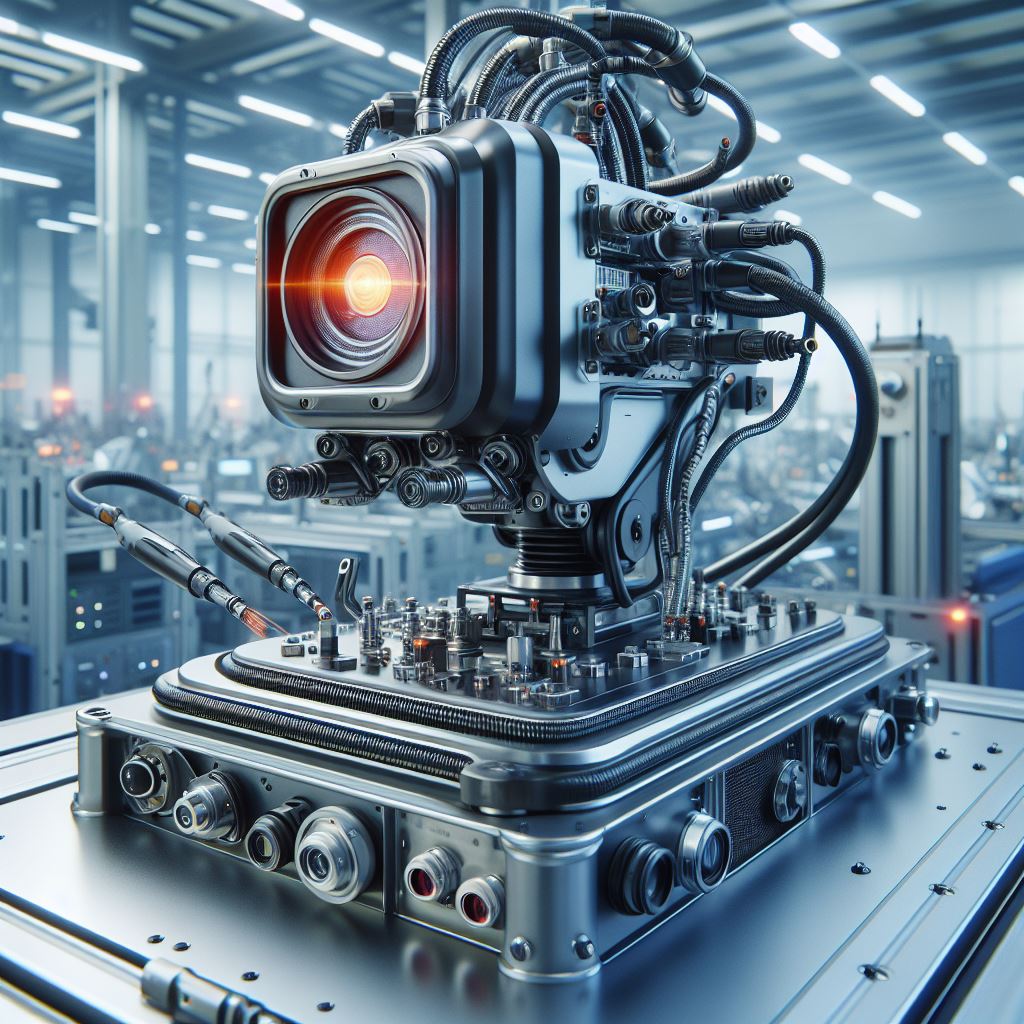

- Vision Feedback System (VFS): The ATWS integrates a high-resolution camera system as part of its Vision Feedback System. This system captures real-time visual data of the welding environment, including material characteristics, joint configurations, and environmental conditions.

- Sensors and Data Processing Unit: The ATWS incorporates a network of sensors, including but not limited to temperature sensors, current sensors, and voltage sensors. The data collected by these sensors is processed in real-time by a centralized Data Processing Unit (DPU), facilitating instantaneous decision-making.

- Artificial Intelligence (AI) Algorithms: The heart of the ATWS lies in its AI algorithms, which interpret visual and sensor data to make dynamic adjustments to welding parameters. These algorithms are designed to adapt to varying welding conditions, ensuring optimal weld quality across diverse applications.

- Adaptive Control Mechanisms: The Adaptive Control Mechanisms of the ATWS dynamically adjust welding parameters such as current, voltage, and travel speed based on the inputs received from the VFS and the AI algorithms. This ensures precision and efficiency in the welding process.

- User Interface and Input System: The ATWS features an intuitive User Interface (UI) and Input System that allows operators to input basic information regarding the welding task. The UI serves as a conduit for the operator’s requirements, enabling seamless communication with the AI-driven control mechanisms.

- Remote Monitoring and Control Module: A Remote Monitoring and Control Module facilitates real-time monitoring of welding processes and allows remote intervention if required. This module enhances operational flexibility and facilitates immediate response to changing welding conditions.

- Safety Mechanisms: Integrated safety features include automatic shutdown in the event of irregularities or unsafe conditions. The ATWS prioritizes the safety of both the equipment and the surrounding environment.

- Training Mode and Machine Learning Capabilities: The ATWS includes a Training Mode that simulates welding tasks. Machine learning capabilities within the system provide constructive feedback, assisting operators in refining their welding skills.

Advantages:

- Accessibility and Inclusivity: The ATWS democratizes TIG welding by requiring minimal operator expertise, making it accessible to individuals with varying skill levels.

- Consistent Weld Quality: The automated feedback system ensures uniform weld quality, minimizing the impact of human error and variations in operator skill.

- Increased Efficiency: The AI-driven automation optimizes welding parameters in real-time, reducing overall welding time and enhancing efficiency.

- Remote Monitoring and Intervention: The ability to monitor and control welding processes remotely enhances operational flexibility and allows for immediate intervention if required.

- Adaptive to Diverse Applications: The ATWS’s adaptive welding modes make it suitable for a wide range of applications, from thin sheet metal to complex joint configurations.

In conclusion, the Autonomous TIG Welding System represents a pioneering technological advancement in automated welding. The integration of the Vision Feedback System, AI algorithms, and Adaptive Control Mechanisms positions the ATWS as an innovative solution for achieving precision, efficiency, and accessibility in TIG welding processes across diverse applications. This patent encompasses the technical details and features that define the uniqueness and advantages of the Autonomous TIG Welding System.