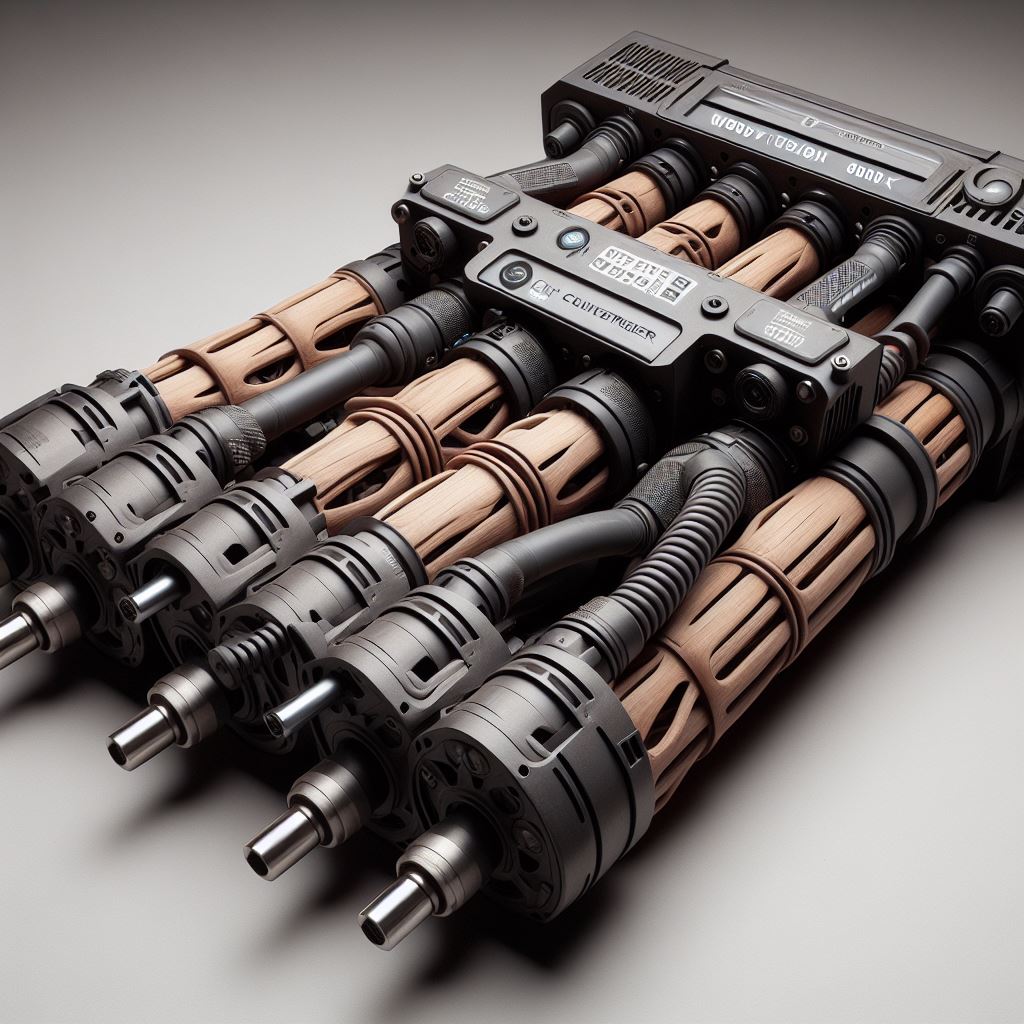

The Wood Fusion Welder 9000X, an avant-garde apparatus poised at the pinnacle of fictional woodworking technology, represents a paradigm shift in the amalgamation of timber through an intricate fusion welding process. This technological marvel seamlessly integrates a confluence of precision engineering, advanced materials, and quantum-level wood manipulation to establish an unparalleled echelon of wood bonding sophistication.

Structural Configuration and Constituent Elements: The framework of the Wood Fusion Welder 9000X is underpinned by a modular architecture, characterized by a superlative titanium-alloy exoskeleton that bequeaths the machine with an optimal blend of structural integrity and lightweight agility. At its core, a Quantum Wood Ionization Chamber (QWIC) serves as the linchpin of the fusion process, surrounded by a meticulously arranged ensemble of oscillating Carbon Fiber Wood Matrix Stabilizers (CFWMS) expressly designed to ensure maximal alignment precision during the welding operation.

Quantum Wood Ionization Chamber (QWIC): The QWIC harnesses the tenets of advanced quantum entanglement, functioning as a crucible for the manipulation of wood at the atomic and molecular levels. Emitting a proprietary blend of Wood Fusion Resonance Waves (WFRW), the QWIC orchestrates a symphony of quantum forces that permeate the wooden substrate, establishing a temporally synchronized milieu that is conducive to the art of fusion.

Wood Fusion Resonance Waves (WFRW): The sine qua non of the fusion process, WFRW, operates as the ethereal catalyst that engenders a controlled quantum state within the wood. The waves, through their omniscient penetration of the material, serve as the architects of alignment, achieving an unprecedented level of precision in the arrangement of wood fibers and creating an ideal environment for molecular integration.

Carbon Fiber Wood Matrix Stabilizers (CFWMS): Enveloping the QWIC, the CFWMS constitute a dynamic cadre of stabilizers that, guided by advanced artificial intelligence algorithms, perpetually calibrate their positions based on real-time feedback from a constellation of embedded sensors. This ensures a continuous, flawless alignment of the wood components, mitigating any potential misalignment aberrations that could jeopardize the integrity of the fusion process.

Operational Dynamics: Operationalizing the Wood Fusion Welder 9000X necessitates the input of precise parameters, including wood type, dimensions, and fusion preferences, into the Quantum Fusion Control Interface (QFCI). The QFCI, serving as the mediator between user inputs and the fusion apparatus, interfaces seamlessly with a Neural Fusion Processing Unit (NFPU), a computational juggernaut that processes the data and instigates the intricate fusion sequence.

Upon securing the wood components within the apparatus, the QWIC activates, heralding the commencement of the fusion process. Simultaneously, the CFWMS engage in a balletic display of dynamic adjustments, ensuring the perpetuation of ideal alignment throughout the fusion operation. As the fusion process unfolds, wood fibers become entangled at the quantum level, engendering a molecular cohesion that transcends the mechanical constraints of traditional wood joinery methodologies.

Benefits of the Wood Fusion Welder 9000X:

- Unparalleled Strength and Durability: The quantum-level fusion process yields bonds of exceptional robustness, surpassing the structural integrity of traditional wood joinery techniques.

- Versatility Across Wood Types: The Wood Fusion Welder 9000X exhibits remarkable adaptability, accommodating an extensive spectrum of wood varieties and configurations, thereby facilitating the fusion of diverse material compositions.

- Sublime Precision: The quantum orchestration of wood fibers ensures a level of alignment precision heretofore unattainable, culminating in flawlessly executed joints with minimal material wastage.

- Temporal Efficiency: In comparison to traditional wood joinery methods, the fusion process, owing to its quantum-enhanced nature, demonstrates a marked reduction in production time, thereby minimizing associated costs.

- Tailored Customization: The Wood Fusion Welder 9000X affords users the capacity to finely calibrate fusion parameters, thereby enabling the machine to cater to an extensive array of woodworking exigencies with an unparalleled degree of customization.

Within the expansive realm of fictional woodworking, the Wood Fusion Welder 9000X stands as a testament to the limitless boundaries of scientific imagination and craftsmanship fusion. This groundbreaking apparatus transcends traditional woodworking methodologies, heralding a new epoch of precision, efficiency, and innovation within the arcane world of wood bonding technologies.

INTERNAL STRUCTURE

1. Titanium-Alloy Exoskeleton: The skeletal frame of the Wood Fusion Welder 9000X is crafted from an advanced titanium alloy, renowned for its exceptional strength-to-weight ratio. This material imparts the machine with structural integrity while ensuring optimal maneuverability during the fusion process.

2. Quantum Wood Ionization Chamber (QWIC): The QWIC encapsulates a specialized composite material featuring layered graphene and carbon nanotubes. This composite structure enhances the chamber’s thermal conductivity, allowing for precise temperature control during the fusion process, while also providing electrical conductivity for optimal interaction with quantum forces.

3. Carbon Fiber Wood Matrix Stabilizers (CFWMS): The CFWMS components are constructed from high-tensile carbon fiber reinforced polymers (CFRP). This material amalgamation grants the stabilizers unparalleled rigidity, essential for maintaining precise alignment during dynamic adjustments. The CFRP also mitigates vibration and resonances, contributing to a stable fusion environment.

4. Wood Fusion Resonance Waves (WFRW) Emission Module: The emission module is comprised of specialized metamaterials designed to control the propagation of WFRW. These metamaterials, often engineered at the nanoscale, facilitate the coherent and directed emission of resonance waves, optimizing their penetration into the wood substrate for an efficient fusion process.

5. Neural Fusion Processing Unit (NFPU): The NFPU incorporates a hybrid architecture featuring quantum processors and advanced neural network modules. Quantum processors handle the intricate quantum computations required for wood manipulation, while neural network modules simulate and learn from the fusion process, continuously optimizing parameters for enhanced efficiency.

6. Quantum Fusion Control Interface (QFCI): The QFCI incorporates a high-resolution touch display layered with a transparent, conductive graphene-based touch sensor. This not only ensures user-friendly interaction but also provides a durable and electrically conductive surface for seamless integration with the quantum processing systems.

7. Embedded Sensors and Feedback Mechanisms: Throughout the Wood Fusion Welder 9000X, an array of sensors is strategically embedded. These sensors, including accelerometers, gyroscopes, and temperature sensors, provide real-time feedback to the machine’s control systems. This data is crucial for the dynamic adjustments made by the CFWMS to maintain optimal alignment and fusion conditions.

8. Quantum Entanglement Modulators: Critical to the functioning of the QWIC, these modulators are constructed from specially engineered superconducting materials. They create and maintain the entangled states within the wood fibers by leveraging the principles of quantum entanglement, allowing for precise manipulation of the wood at the atomic and molecular levels.

9. Fusion Chamber Enclosure: The fusion chamber enclosure is composed of a high-transparency borosilicate glass composite, designed to withstand extreme temperatures and provide a clear view of the fusion process. This material ensures both safety and visibility during the operation of the Wood Fusion Welder 9000X.

These sophisticated materials contribute to the seamless functioning of the Wood Fusion Welder 9000X, ensuring its capability to achieve unparalleled precision and efficiency in the fusion welding of wood. The amalgamation of advanced alloys, composites, and quantum-enhanced materials epitomizes the cutting-edge nature of this fictional woodworking apparatus.